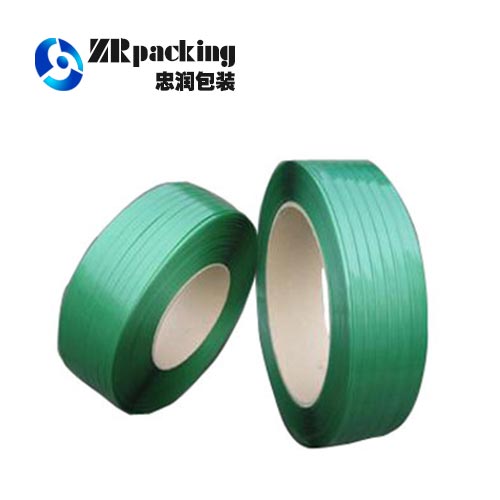

PET plastic belt (also known as PET belt) is a new type of strapping belt that is popular in the world. It is widely used in replacing steel belts and PP packing belts due to its low cost, beautiful and durable, environmentally friendly recycling and high degree of automation. New strapping packaging materials.

Widely used in steel, aluminum, chemical fiber, cotton spinning, tobacco, paper, ceramics, wood, metal cans and other industries.

Strong tensile strength: both steel-like tensile strength and impact-resistant ductility. PET packing material is (polyester), which has strong tensile strength and is close to the steel strip of the same specification. Several times the ordinary plastic belt, it can ensure the safety of your products.

Low elongation: Elongation is only one-sixth of that of polypropylene (PP) tape, which can maintain tension for a long time.

Strong temperature resistance: The melting point is 260 degrees, and the use below 120 degrees is not deformed.

Good flexibility: no sharp edges of steel belts, safe operation, neither hurting hands nor damaging the bundled objects.

Beautiful and rust-free: no steel belt rust pollution of the bundled objects, the color is bright and can be seen.

Good economic efficiency: The length of 1 ton plastic strip is equivalent to 6 tons of steel belt, and the unit price per meter is lower than steel belt, which can reduce the cost for you.

1. PET plastic steel belt is a kind of packaging material with good tensile strength and excellent welding performance.

2. It has a good tension and retention ability, and does not slack after a long time of bagging, thus ensuring excellent impact resistance of the goods in long-distance transportation.

3. It can be packed directly with PET plastic belt, and the goods will not be damaged or corroded.

4. Good flexibility, easy and safe operation. PET packing belt has plastic characteristics and special flexibility. It can avoid the scattering of the belt caused by bumps during transportation and ensure the safety of transportation. PET plastic belt has no sharp edges of steel strip and will not be scratched. The packaging will not hurt the hand, and no special tools are needed for cutting. Even if the binding is tighter, it will not hurt when cut.

5. Excellent weather resistance, maintaining good stability between -50 °C and 100 °C. Due to the material and manufacturing process factors, PET belt can adapt to various climate changes, high temperature and humidity resistance, unlike the steel belt damp and rust pollution environment and loss of tensile strength, so that the strength of the bale is reduced.

6. Beautiful appearance, environmental protection, and recyclable use. Convenience and environmental protection: Because PET belt is light in weight and easy to handle; it is small in size and saves warehouse space; used PET belt is easy to recycle and meets environmental protection requirements.

7. Good economic returns. The density of PET steel strip is only 1/6 of the density of steel strip. The price per unit length is relatively low. The length of 1 ton plastic strip is equivalent to the length of 6 tons of steel strip, and the cost per metre is lower than that of steel strip.

Dongguan Zhongrun Packaging Materials Co., Ltd.

Contact: Mr. Wang

Contact information:

Phone: 0769-22851507

Mobile: 13316698383

Mobile: 18929253062

Fax: 0769-22851507

Q Q: 1037000342

E-mail: zrpacking@sina.com

Address: No. 8, Baima Cuiyuan Street, Nancheng Street, Dongguan City